Thermal Mass and Sustainable Building Design

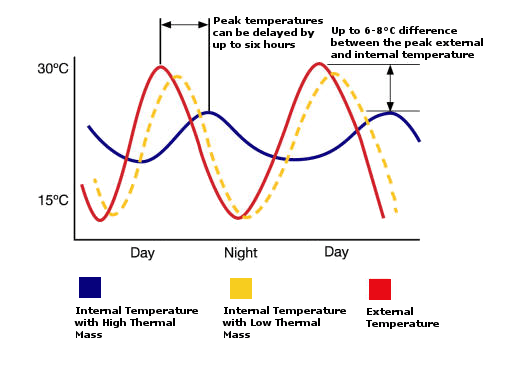

Thermal Mass. You may have heard this term before when investigating the structure or construction materials of a building, but what exactly is it? Put simply the thermal mass of a material is its ability to absorb and store heat energy. This stored energy can then be emitted back into the space at a later time once the temperature within the room has dropped.

With U-values having a maximum Part L Building Regulations requirement, the thermal mass of the construction is often overlooked. However it really shouldn’t be. The thermal mass of a material can help to decrease the overheating within a room, lower cooling energy usage and reduce the overall carbon emissions of a building.

To describe the process in simple terms: when the sun is shining and the external temperature is high, the materials of the building, providing they have sufficient thermal mass, will absorb some of the heat energy within the room. This helps to keep the temperature within the room lower for longer, allowing any cooling systems installed to run less often. This reduces the cooling systems energy consumption and therefore the buildings overall carbon emissions.

At night when the sun has gone down and the external temperatures are lower, secure night time ventilation can be used to cool the materials down. This causes them to emit their stored heat back into the space, resetting to begin the process over again the next day.

Which Materials have the best Thermal Mass?

Now we know the general idea as to how thermal mass can help to reduce the temperatures and cooling energy usage within a building, which materials are the best to use.

To determine the thermal mass of a material we have to know its Volumetric Heat Capacity. Which can be found by multiplying its density by its specific heat capacity.

Heavyweight materials such as concrete and brick have a high volumetric heat capacity and therefore a building constructed from these materials would have a high thermal mass. Lightweight materials such as timber and insulated panels have a low volumetric heat capacity and therefore a building constructed from these materials would have a low thermal mass.

The typical density, specific heat capacity and volumetric heat capacity of some common materials can be found in the table below.

| Material | Density (kg/m3) | Specific Heat Capacity (kJ/kg.K) | Volumetric Heat Capacity (kJ/m3.K) |

| Brick | ≈ 1800 | 0.8 | 1440 |

| Concrete Slab | 2400 | 1 | 2400 |

| Concrete Block (Dense) | ≈ 2000 | 1 | 2000 |

| Concrete Block (Light) | ≈ 650 | 1 | 650 |

| Timber | ≈ 450 | 1.2 | 540 |

| Plasterboard | 668 | 1.1 | 735 |

| Water | 1000 | 4.2 | 4200 |

The table shows that the heavyweight materials have a much higher volumetric heat capacity and therefore a building constructed out of these materials would provide much more thermal mass. Perhaps surprisingly, water is one of the best materials to use when a high amount of thermal mass is required.

Phase Change Materials (PCMs)

The use of heavyweight constructions to provide thermal mass in buildings isn’t always possible, for example where there are weight restrictions on the site or when retrofitting existing buildings. So what can be done to increase the thermal mass of lightweight buildings to help improve the indoor environment.

The answer comes in the form of Phase Change Materials, also known as PCMs. Phase change materials such as the Knauf Comfortboard Plasterboard or Dupont Energain panels, use the latent heat potential of their construction material, typically Paraffin Wax, to melt and change phase from a solid to a liquid when heated up.

This change of phase absorbs heat energy from the room, helping to maintain it at a comfortable temperature for longer. At night, with the introduction of cooler air through secure night time ventilation, the heat is released back into the room and the wax solidifies ready to start the process again the next day.

Two layers of PCM plasterboard will provide the equivalent thermal capacity as a 100mm concrete wall, at a fraction of the weight.

How we can Help?

At Elmstead Energy Assessments & Building Services we can use our expertise in the Dynamic Simulation Thermal Modelling of buildings to test and analyse a range of different thermal mass scenarios.

We can simulate the year round use of your building with lightweight or heavyweight constructions, we can even include for the use of Phase Change Materials.

We can then collate the results and provide an easy to understand report of the findings, highlighting the differences in indoor thermal comfort, cooling loads and carbon emissions.

If you are considering the use of thermal mass to help your building pass UK overheating regulations such as BB 101 or CIBSE TM52, or to help reduce the carbon emissions in order to pass Part L of the building regulations, please contact us today.